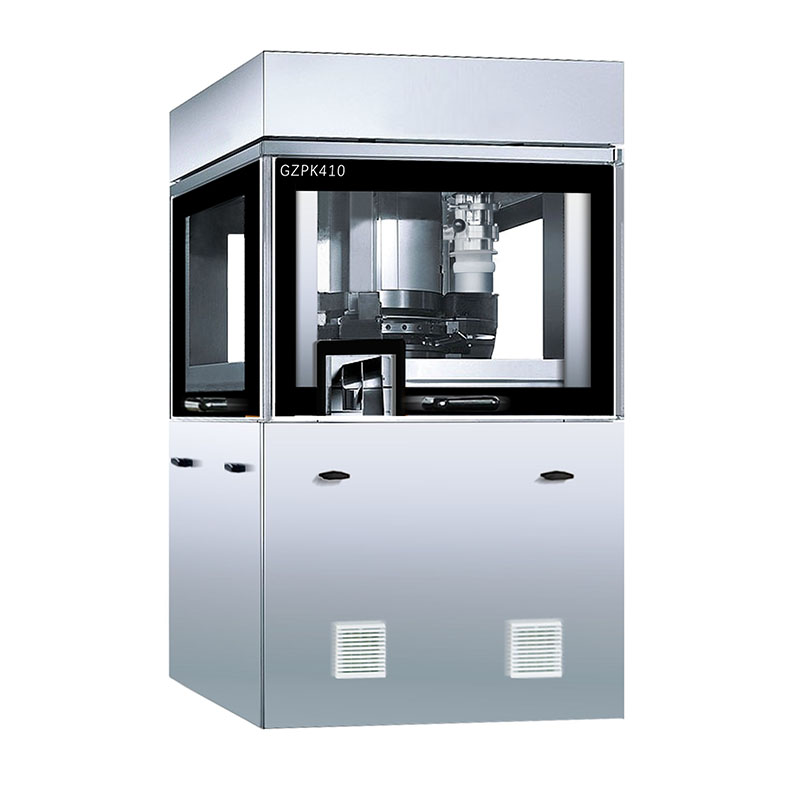

GZPK620 Bi-layer high speed tablet compression machine Pharmaceutical pill making machine

Features

1. It has function of automatic control tablet weight and the function of waste tablet identification and automatic rejection.

2. With powder absorbing device for absorbing indoor dust.

3. Adopt stainless steel material,it can keep the surface glossy and prevent cross contamination that meets GMP.

4. Equipped with organic glass windows and all sides plate can turn on and clear up for a easy maintenance.

5. All controller and operating parts with a reasonable layout.

6. Equipped with variable electrical frequency speed control device which is convenient for operation.

7. With overload protection device,when pressure overload, machine will stop automatically

8. Transmission system is sealed at the bottom of main tank, it is a safe separation of independent components to avoid pollution. The transmission of infiltration in the oil pool, that is easy for heat output and also wearable.

Video

Specification

|

Model |

GZPK620-45 |

GZPK620-55 |

GZPK620-65 |

|

Number of Punch Stations |

45 |

55 |

65 |

|

Punch type |

D EU1"/TSM1" |

B EU19/TSM19 |

BB EU19/TSM19 |

|

Max.Main pressure (kn) |

100 |

||

|

Max.Pre-pressure (kn) |

16 |

||

|

Max.turret speed (rpm) |

75 |

75 |

75 |

|

Max. capacity (pcs/h) |

405000 |

495000 |

585000 |

|

Max tablet diameter (mm) |

25 |

16 |

13 |

|

Max tablet thickness (mm) |

8 |

8 |

8 |

|

Main motor power (db) |

≤75 |

||

|

Power (kw) |

11 |

||

|

Voltage (V) |

380V/3P 50Hz can be customized |

||

|

Dimension (mm) |

1400*1500*1900 |

||

|

Weight (kg) |

3300 |

||

Highlight

● Force-feeding device controls the flow of powder and ensures the accuracy of feeding.

● It can make double layer tablet.

● With automatic rejection for unqualified tablets.

● Automatic lubrication system for a lifetime running.

● Protection function for motor, upper and lower punches.

● Pressure adjustment system for main pressure and Pre-pressure.

Products categories

Our Weekly Newsletter

It is a long established fact that a reder will becontent by

the readable of a page when looking.

-

E-mail

-

Phone

-

Whatsapp

-

Top